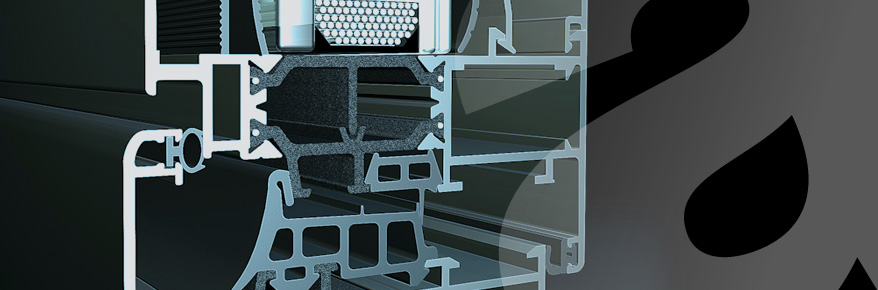

Energy saving. At All.co this is more than just a slogan. We believe in the conservation of resources and do all we can to ensure that our products accurately reflect our vision, combining comfort with best possible performance. This explains our constant commitment to development of the thermal break, a technology which provides an efficient barrier to thermal dispersion by the insertion of highly insulating material into the internal cavity of extruded products. Our pride of place architectural products (for example our profiles for doors and windows) are produced using the most advanced thermal break solutions. For this reason they achieve excellent results in performance tests: they are an efficient barrier against heat and cold, have excellent acoustic qualities and supreme resilience to corrosion.

A good thermal break requires careful profile design and great precision in the manufacturing phase. All.co carries out thermal break development in its in-house Research Centre and all processing is performed in Group factories, which are equipped with the most up to date technology. Two All.co factories, in Pisa and Padua, are employed in the assembly of thermal break profiles and all contain high precision equipment. Some All.co thermal break profiles have received Qualitherm certification for their construction quality and performance.